Engineered wood is a popular type of wood that is commonly used in construction and furniture making. It is made by combining multiple layers of wood, with each layer placed in a different direction, which makes it stronger and more durable than solid wood. In this article, we will take a closer look at what engineered wood is, how it is made, its benefits and drawbacks, and some of its most popular uses.

What is Engineered Wood?

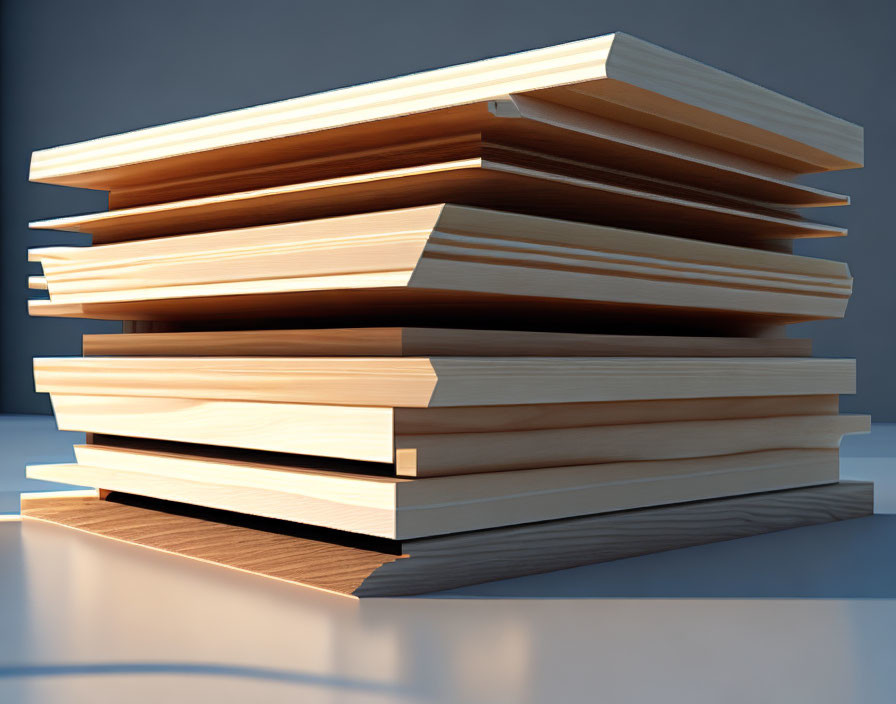

Engineered wood is a type of wood that is made by combining different layers of wood. These layers are usually made of thin wood veneers that are glued together, with each layer placed in a different direction. This process is known as cross-ply construction, and it is what gives engineered wood its strength and durability.

Unlike solid wood, which is cut directly from a tree, engineered wood is made from wood that has been processed into thin sheets. These sheets are then stacked together and bonded with adhesive to form a solid piece of wood. Because engineered wood is made from thin layers of wood, it is more stable than solid wood, which can expand or contract with changes in temperature and humidity.

Types of Engineered Wood

There are several different types of engineered wood, each with its own unique characteristics and uses. Here are some of the most popular types of engineered wood:

- Plywood – Plywood is made from thin sheets of wood veneer that are glued together. The layers are usually arranged with the grain running in alternating directions, which makes the wood strong and durable. Plywood is commonly used in construction and furniture making.

- Oriented Strand Board (OSB) – OSB is made from wood strands that are bonded together with adhesive. The strands are usually arranged in a cross-hatch pattern, which makes the wood strong and durable. OSB is commonly used in construction and sheathing.

- Medium-Density Fiberboard (MDF) – MDF is made from wood fibers that are bonded together with resin. The wood fibers are usually mixed with a binder and then pressed into sheets. MDF is commonly used in furniture making and cabinetry.

- Particle Board – Particle board is made from wood particles that are bonded together with resin. The particles are usually mixed with a binder and then pressed into sheets. Particle board is commonly used in furniture making and cabinetry.

How is Engineered Wood Made?

The process of making engineered wood varies depending on the type of wood being used. However, the basic steps involved in making engineered wood are as follows:

- Slicing – The wood is first sliced into thin sheets, usually around 1/8 inch thick.

- Drying – The wood sheets are then dried to remove any excess moisture.

- Sorting – The wood sheets are sorted by quality and thickness.

- Gluing – The wood sheets are then glued together, with each layer placed in a different direction. The glue used is usually a type of resin.

- Pressing – The glued sheets are then placed in a press and compressed under high pressure and temperature to form a solid piece of wood.

- Finishing – The finished piece of engineered wood is then sanded and finished to achieve the desired texture and appearance.

Benefits of Engineered Wood

- Stability: Engineered wood is more stable than solid wood, as the layers of wood are arranged in a way that minimizes warping and splitting.

- Durability: Engineered wood is strong and durable, making it ideal for use in construction, furniture, and other applications where strength and durability are important.

- Cost-effective: Engineered wood is often less expensive than solid wood, making it a cost-effective option for many applications.

- Sustainability: Engineered wood is made from renewable resources, such as wood fiber, and can be produced with minimal waste.

- Versatility: Engineered wood can be used in a wide range of applications, from flooring and furniture to construction and cabinetry.